Larsboat (Breve)

After building an AF4

power skiff, an AF3

sailing sharpie, and an Oracle

rowboat, I decided that the next logical project was a double-paddle

decked canoe. Since my previous projects had all been designs

by Jim

Michalak, I decided again to build one of his boats;

in this case, it would be the "Larsboat."

Construction was begun in August and the boat

was complete and ready to "splash" by early October.

This just happened to be the three-year-anniversary of my boat

building hobby, which has now produced four boats.

My boats have all been built sturdily, but cheaply,

of commonly-available"lumberyard" materials, and the

Larsboat was not to be an exception. The plywood used was 5.5

mm "Ultraply," a somewhat "high-grade" of

underlayment similar to the commonly-seen luan, but hopefully

made with a bit more quality. It's cost was about twice that

of the luan, about $20.00 per sheet.

Certainly you have noticed the "breve"

part of the title.

The workmanship on my three previous boats is far from perfect;

the joinery work would not pass muster in a yacht yard. Neither

would the finish work. Yet all of them, despite their imperfections

and sometimes crude finish, do the jobs they were intended to

do. The Larsboat turned out to be no exception to any of the

above.

My Larsboat is 6 inches shorter than it was supposed

to be. This design is basically a Toto lengthened by 30 inches.

Jim points this out very clearly in his description of the boat.

And the drawings show that the amidships station has 30 inch

spacing, whereas the rest of the stations have 24 inch spacing.

While laying-out the stations on the sheets of plywood, however,

I overlooked this one long station and put them all on 24 inch

centers, so there is 6 inches missing from the middle of my

boat.

I decided to sheath the outside of the hull up

to the gunnels with Xynol cloth and epoxy from Raka. The interior

of the cockpit is sheathed with epoxy and 6 ounce glass cloth.

The interior areas of the bow and stern where not sheathed.

All seams in the areas that were to be sheathed,

received a single layer of 3 inch glass seam tape, while 2 layers

of seam tape were applied to seams in the non-sheathed areas

of the boat.

Behr-brand latex primer and latex exterior house

paint provided the finish, with the exception of the coamings

and the hatch cover, which were saturated with house deck stain.

As constructed, the boat weighs 83 pounds and

feels extremely solid, even when I (a BIG guy) climb in. The

interior cockpit sheathing could be dispensed with, for a savings

of about 8 lbs or so.

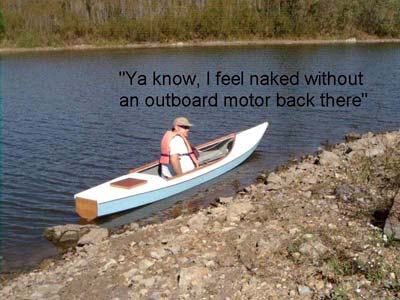

Jim went along on the first outing and had a chance

to try-out the boat, as the photo above shows. He could find

little fault with the way it handled. I found the boat easy

to paddle with both a double-bladed kayak paddle and also with

a single-bladed canoe paddle. I find sitting cross-legged on

an ordinary boat cushion to be a comfortable paddling position.

I do suggest keeping a sponge in the cockpit in order to remove

the small amounts of "bilge water" that the double-paddle

brings aboard.

All in all, although my larsboat did come up a

little short in length, that appears to be the only area in

which it "comes up short."

Max

(editors note: Max writes the popular

Duckworks column "Obsolete

Outboards"

and moderates the Michalak

discussion group)