|

A Fiberglass Matting Alternative

by Dale Ruth

Hi Chuck,

I wish to submit a hopefully fresh idea that I experimented with last year that

might interest " economy " minded boatbuilding readers.

I was redoing my house windows last year with Vinyl-Coated ( PVC ) Fiberglass

Window Screen Fabric ( 18 X16 conventional mesh ) when I got the uncanny notion

that since this is afterall fiberglass mesh and exceptionally strong, durable and rot resistant

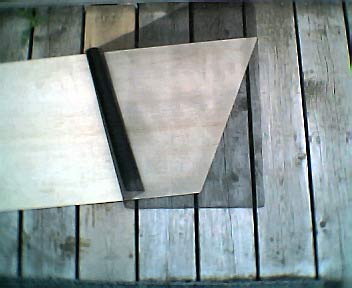

material at that, I decided to apply a small piece to an old weathered scrap piece of

exterior fir plywood just to see what the results would be. It bonded surprisingly well as

I thought for sure the polyurethane resin would not adhere the mesh's vinyl coating to

the plywood. I gave it only one coat ( when the resin cured I cut a deep slit in the center

as shown in order to allow moisture to penetrate ), a little sanding and left it exposed to

all the harsh elements that our northern climate can throw at it including all winter long.

The plywood piece lifted, rotted and checked in a few unprotected areas near the mesh piece

but amazingly no separation or deterioration occurred whatsoever - it remained in tact as

though it were welded to the plywood - it is permanently affixed !

This was quite promising so I decided that since my small boat

requires the bottom to be sanded, resealed and repainted anyways

I went ahead and draped the entire bottom using this fibreglass window screen

mesh. The mesh went on very well, cutting was simple including no worries of

fray edges, air-born glass particles or annoying itching which is so often the case

when using fibreglass matting. Applying 3 coats of resin was another easy

task as the mesh filled with resin evenly and smoothly.

The biggest concern I had was the fear of multiple cracks occurring when

stepping into the boat with my 185lb weight. To my amazement this did not

happen at all. Repeated stepping in and out of the boat ( with my 14 yr son

on board at times ), the throwing in of all kinds of gear including running the

boat dozen of times up on to and off gravel, rocky and sandy shorelines for the

past 4 months including not covering the boat when stored outside has proven

that this fibreglass screening has stood up very well to normal use.

The pic below shows intentional removal of paint in a small area of the completed

bottom so that the mesh can clearly be seen how it appears embedded in resin - it acts

very much like rebar in cement. I am completely satisfied with the results and it

only cost me next to nothing for the amount of mesh I needed to do the whole bottom and I

still had some left over to boot. Smaller or tighter weaved fibreglass mesh (20 X 20)

is also available.

I'm planning to build a "12 ' - Jonboat" found on the "Free Boat Design Resources"

webpage. Looks like a solid but heavy boat design (1978) so I will incorporate modern building

techniques to reduce weight. I feel confident in using this material to do the transom, stem

and side sections as well. Perhaps I will also do all the seams with this stuff, but I will

definitely test that before doing so.

Dale

|