| DIMENSIONS |

|

|

LOA/LOD/LWL |

= |

15.08’ |

BEAM |

= |

8.00’ |

Hull Length:Beam |

= |

11.4 |

Wet area |

= |

41.08 sq.ft. |

Waterplane |

= |

27.54 sq.ft. |

Cruising Displacement |

= |

631 lbs @ 5.25” draft |

Immersion |

= |

140 lbs/inch. |

Moment to trim 1” |

= |

110 ft –lbs |

Bridgedeck |

= |

8 x 4 ft ply sheet, 16” clearance, 59” span |

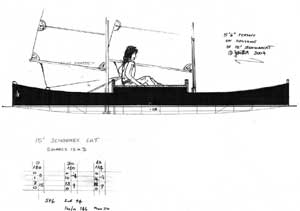

(click image to enlarge)

Part One; 0 through 76 hours of work.

Jeff Gilbert has designed a boat called Roonio which I started building on 12/09/04. It’s an asymmetrical cat that was originally designed to both shunt and tack. At about 200lbs and a Draft of about 4.5”. The hulls are 15’6” long with a 19”/hull beam Max Beam 8’, and a 4’x8’ bridge deck. The hulls attach by wingbolts and, in theory, the whole thing is car toppable, but I’ll most likely find a second hand trailer.

The Start

(click images to enlarge)

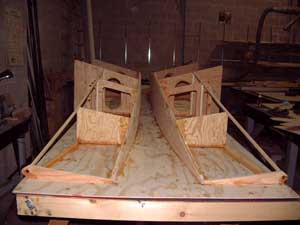

The outsides of the cat are flat so I laid them both out at once on a 4’x16 butt joined piece of ¼”ply. Bottom to bottom, its easy to see any mistakes by mere comparison. Also, laying out the bulkheads is easier and you are sure of symmetrical hulls. This also allows bracing from bottom to bottom when gluing them on, reducing clamps.

Notice that on the center bulkheads there is a piece of angle iron clamped on to square up the bridge deck bulkheads. There will be fillets on all the corners on the inside, but fiberglass all over is not necessary though I will put them on the outside bottom edges.

Here are the inside curved logs going on, tacked to the bulkheads. I find that a pneumatic staple gun goes a long way in making a boat fast and square. Stainless steel staples were used and overdriven to seal over with epoxy.

Next, the bottoms were attached at a right angle to the 4’x16’ base. Note braces.

Then the fore-decks with access ports for drying-out/sealing..

There will be four mast positions, one each fore and aft of the cockpits on both hulls. The rig is two sails in any of four positions, giving you a lot of sail area but retaining an already low center of gravity and effort.

Mast Steps

Not that you need any help on a cat, but boy will this thing fly with the extra sail area! Next the hulls are cut apart from each other, and the inner curved wall is added. Both flat side and curved side were cut and routed down to size. (Picture shows Schooner Monohull Option)

Notice the tabs for bolt holes on the bows and sterns: you can take the flat sides and bolt them together to form a schooner. I don’t think I’ll actually use this feature, but hey, I’ll keep the option open. The bottoms will be fiber glassed. Mast steps were installed, then the last of the fore decks.

Hulls to date.

Design C178

ROONIO THE CAT

DESCRIPTION

Roonio is a simple demountable 15-foot plywood catamaran designed for home construction. Somewhat experimental, the boat is so easily propelled that the design rig comprises 2 x 40 sq foot home-built sails on revolving masts in any of 4 mast positions. Being reversible, the yacht can be shunted or tacked. Steered by weight shifting or paddle, Roonio is sailed from an 8 x 4-foot Bridgedeck made of a strengthened single ply sheet. Asymmetric hulls limit lee drift by the flat outer hull sides combined with the bottoms extended inboard to form vortex boards.

The boat requires no reconstruction, but rather the addition of foils to convert to a more recognizable, common house-trained cat. Standard kick-up rudders purpose built or filched from a less pristine beastie will put steering on a more proven footing. And those who crave maximal windward ability can temporarily sacrifice the 5¼”sailing draft by using a single dagger board to windward or leeward since the boat is reversible. This dagger can go through the bridgedeck and one vortex wing if using the forr’d biplane rig configuration, but would have to be well aft if sailing as a schooner-proa with both masts in one hull. This could best be achieved by adding daggerboard rungs to the outer side of one hull.

In other words, the more performance one wants from this boat, the more work needs to expended in adding tuned foils and their support infrastructure, and the less flexible the boat becomes. In its most complex form, as a proa with a kick-up rudder either end and a dagger or two to shift, you would probably need two to shunt it quickly.

On a day or weekend sail I’d take it out with a simple biplane rig, a steering paddle and no daggerboards, and a small 2 HP outboard motor with a full tank. Not optimal, but simple and safe, and if you had a destination in mind, if there was a mild time constraint, I’d motor to gain leeway or beat a calm. As a boat like this reaches and runs so very fast, I wouldn’t be starting a motor under any other circumstances, hence one couldn’t use much gas. If its calm the long steering paddle/oar can be used as a sweep. A lot of leverage can be gained by using the paddle thru a hole in the bridgedeck rear rail, and one would sail with sheets in one hand and paddle in the other. Loping along on a easy reach I’d thread the sheet tail(s) thru a hole in the paddle handle, so that you could free a hand by pulling the sheet(s) up thru the handle and twisting 180deg to lock them off temporarily.

Much more on rigging follows.

Roonio is designed for ease of construction & robustness more than low weight. To make this boat really light would involve a complex system of frames and a vulnerable fabric not in tune with the intended use or build effort. Thus though it is car-toppable with the hulls laying flat on their sides within the outer Bridgedeck rails, it will be a job to unload hulls alone. The boat is designed to perform best with a crew of two anyway, but those who choose to sail solo may prefer to lash the Bridgedeck on a standard car trailer to simplify assembly and launching.

HISTORY

The design was born of a June 2004 letter from Mr Jeremy Eisler, who wished to pursue the following concept. His requirements were well thought out and detailed, yet simplicity shone through. In short, Jeremy’s idea was appealing and irresistible.

Last email from Jeff to Paul as he packed to go to Tasmania.

More to follow as build progresses.

Paul Moffitt