I recently have gotten my Trilars sailing. I would like to make a few comments for others who might build one. I would like to suggest that you follow the plans and don't make changes. I have found that when I make changes, even ones that seem trivial, I later regret them. For example, when I built Trilars I made some butt blocks larger than Jim suggested on the plans. The result was a distorted bottom. In the future, I would avoid the use of butt blocks altogether on smaller boats. I would use just a layer of fiberglass on both sides of the plywood.

Another point is the use of lauan. The plywood panels are long and very narrow. It's best to fiberglass them for strength before putting them on the frames. I had some breaks in the plywood while I was trying to get the panels on the frames and stitched to each other. I just fiberglassed the panels back together (they didn't break completely through, but almost, due, I think, to voids in the middle layers).

In time, lauan starts to delaminate. I think if you coat it with epoxy, it will greatly reduce the delamination. Light weight fiberglass and epoxy on both sides would be better, but also heavier and a bit expensive. As it is now, I am already seeing some isolated spots where there is delamination on the main hull, which is a year older than the amas. I am fiberglassing the worst ones, and epoxy coating others that aren't as bad. I am hoping that my boat is not going to look like a patchwork quilt in, say, 5 years.

I managed to break the leeboard the first time I took the boat out to sail it. It was trying to take off without me, carrying my wife (who doesn't really know how to sail). I pulled the boat back hard, apparently onto sand, breaking the board. Since then, I built another board out of southern yellow pine, two layers of one half inch ply, and I added a layer of fiberglass on the outsides for strength. It is working well so far.

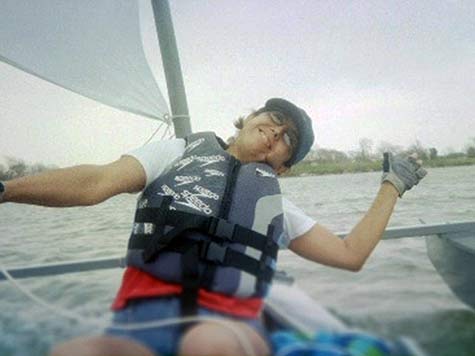

My wife, Maria, is handling the sheet and clowning for the camera in the first photo.

I think that the sail Jim has on the plans is fine. Other builders have used larger sails, but I don't think it is necessary. And I recently put reef points into my 59 square foot sail, just in case. I have sailed the boat in 10 to 15 mph winds and they are not a problem. But 30 mph winds may be a different matter with this sail.

This is a wet boat, and making the coaming as Jim has it in the plans might help reduce the spray. In any case, I think a spray skirt is almost mandatory with this boat.

I spent roughly $500 on the boat, and I think that makes it a bargain. It is quick and responsive. Very fast downwind and on a reach. Compared to the Piccup I had a few years back, it is fast upwind, too. I have sailed it mostly in rivers in this area, and noticed that the spray is worse when sailing upwind in shallow areas. I think this boat begs for deeper water. I have had a few problems tacking, but I think that is mostly due to my inexperience as a sailor. You need to have a little speed going into a tack, and that will carry you through.

The grumpy old man in the other photo is me.

The boat can be kept bolted together on a trailer for convenience, as it is just less than 8 feet wide. Or it could be cartopped, if you have or can make a good cartop carrier. Even so, if you use this method, it is best to have help in order to avoid putting scratches on your vehicle. The main hull is long and heavy enough to make it difficult to handle at times.

***** |