Custom Search

|

| boat plans |

| canoe/kayak |

| electrical |

| epoxy/supplies |

| fasteners |

| gear |

| gift certificates |

| hardware |

| hatches/deckplates |

| paint/varnish |

| rope/line |

| rowing/sculling |

| sailmaking |

| sails |

| tools |

| join |

| home |

| indexes |

| classifieds |

| calendar |

| archives |

| about |

| links |

| Join Duckworks Get free newsletter CLICK HERE |

|

|

| Change - Part Four |

by Dan Rogers - Diamond Lake, Washington - USA |

Part One - Part Two - Part Three - Part Four Remove from heat, stir occasionally, let cool…A day or two short of two weeks ago, I pulled this heavy-as-a-baby elephant Chevy six out of a down at the heels 45 year old runabout hull. I replaced the floor and motor mount/bilge sump with ¾” mdo plywood. This project neither had a budget, nor a place on the punch list. All I was gonna’ do—at first was to re-purpose the engine and outdrive for Old Salt, the 1959 vintage Glasspar Seafair cuddy cabin boat that was brought back from the dead a couple years ago. Old Salt has not been lucky with engines, and the thought of putting this simple four-stroke Detroit Iron in her belly had me all excited. Then, I did some research on just how heavy and big that upright, in-line monster really is. Six hundred pounds, heavy. And, four feet long, big. Rational people would have sent the whole thing to where things like that normally go. While, I do consider myself more or less rational; I cannot claim to be normal. Sooooooo. This is what has resulted from a half-dozen or more trips to the local lumber yard. And, about 12, very intense days and nights. No, I ‘m not even close to done. But, here’s the deal. If I was Sisyphus’ personal trainer, I’d be in there with him getting a real good run at pushing that boulder up the hill. I figure, if you can get a really good start on a project, maybe you can get finished before you realize just how tired you are. Something, like that.

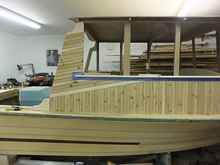

The astute observer will, of course, note that only the starboard side is even close to put together. But, for instance, those cedar staves glued to the cabin sides. There’s a bazillion of ‘em. I cut ‘em all out of standard lumberyard cedar 2x6 lumber. They had to be sanded smooth. They had to be bullnosed on the router table. They all had to be cut at the correct angles, and trimmed a half-kerf at a time. Then each one had to be glued on and… Well, anyway, there’s a whole lot of walking back and forth and doing repetitive stuff with sharp things real close to fingers. And, that doesn’t count all the substructure that needed to be in place first, to hang the gingerbread on. I think Roughneck looks better in person, than with the lousy camera angles that I can use at the moment. There’s so much equipment and shelving and stuff in the way, I can’t really get a flattering angle. I even tried standing on several gallon paint cans stacked next to the paint shelves, and holding the camera waaaaayyy back over my head. Since I only had a vague idea what the results were supposed to look like, last Sunday when I stated turning perfectly good plywood into noise, dust, and 2” wide strips. I give myself a passing mark for getting the structure to stand on its own. Two days ago, things looked a bit more skeletal than they do now.

Once again, the acute observer will note that duct tape and spring clamps are not considered adequate attachment methods for a seagoing vessel. And, I hasten to agree. But, I already admitted that I can’t draw a decent rendering of the mental image. So, this is the method of choice, for figuring out how things should go together. I wonder if Noah had spring clamps. He certainly had to have duct tape. Heck. I’ll bet there was even duct tape in King Tut’s seabag. Then about a day ago, things started to take shape. Sort of.

Fortunately, not this particular shape. Some, Really Cool Ideas, should never see the light of day. And, I suppose this is one of them. I wonder if this is really why the etch-a-sketch was invented. The metacentric height/weight and moment guys will have a conniption if they ever see how much structure I crammed above the deck line. Well, the thought of this cabin wracking and swaying in a seaway just didn’t sit well. And, besides, all the Dinty Moore cans will be stowed down low, on center line. Kind of like how Lord Hornblower required all his brass monkeys to be stowed with their balls down low. You do know about brass monkeys, don’t you? As late as last night, I was still thinking that I’d blank in the aft window, that I spent most of a day framing in, the day before. And, check out the nifty use of duct tape to draw in the waistline.

But, this morning, I asked the boat. She said, “Two windows is OK. Three is better.” So, three it is. But, by lunch time, this is about all I had to show for all the dust and noise, and walking from tool to tool, and moaning when it didn’t fit.

And, then, the swing shift crew came on, and things picked up a bit.

But, the boss wasn’t quite satisfied, so things got going ever quicker. The window frames are sort of mocked up with “real” parts. I may just glue ‘em in tomorrow. Or change it. I’ll ask the boat.

The leading edge of the visor actually has more shape than this camera angle would offer. And, the remaining foredeck is still 3 feet long. Even after I planted a 16” high trunk cabin on it. And, of course the rest of the original foredeck will be excised in the next few days. Not tonight. It’s Sunday. I knocked the night crew off early, at 2200. I was feeling generous. Told ‘em to take the rest of the day off, and have a good time. On me. An epilog, of sorts. I say “of sorts,” as this is still an incomplete story. “Nice work Dan, Those angled strips are very appealing; they really add to the look and feel of the house. That has to be a tremendous amount of labor cutting and shaping all those to fit and then attaching. You are to be commended on your drive and perseverance - and ingenuity!!! Where do you find the time? You must be retired, retired master carpenter.” Tom Thanks, Tom. Yes, I’m retarded. I guess the time comes from not watching TV, drinking beer, or taking smoke breaks. Mostly, a Sysphus-like tenacity (obsessions). Although most folks would also define that as insanity (doing the same thing over and over again, hoping for different results.) Lately, I conclude that I’m either in a race with the orthopod, or the undertaker. Or, both. Kate says, “But you have all winter…” And, I respond, “No, if I don’t get this one more or less set in concrete, I’ll just come up with a new set of ideas and never get anything done…” As far as carpentry, I’m just a self-taught hack, who insists on doing things differently. Those strips were an eleventh hour attempt to soften the boxiness necessary in getting standing headroom and enough length to offer space for all the “cruising amenities.”

I needed to keep the quarters low to climb in and out - although aesthetically, a sloped coaming would have done the trick much better. Same old problem of trying to cram a 26 footer into a 17 foot hull. But, I can swing a cat in the putative pilot house. And, yes, this is possibly the boat that I get to go back to Desperation Sound in. That’s sort of the daydream at the moment. This is the jumboized version of the small tuglet and small shanty barge that I tried last year. I concluded that they, while offering most of the capabilities I was seeking, on paper, were just too small for my aging frame. Standing up under a roof, and watching the rain fall from inside - next to a cabin heater - becomes a mission essential feature after a long career of standing in an open sailboat cockpit with that steady drip from topping lift to shirt collar. Hence the third set of windows. It looks a lot better proportionally with a “landau” top/”formal roof line” as the car ads used to tout. But, things were getting a bit cave-like inside. So it goes. As far as master carpentry: I’m still agog at your precision with the 7-sided hexagon. I want to do something similar with the corner posts outboard of the 3-pane windshield. (Only a mental image is available at the moment.) Only, the staves have to not only bevel, they have to taper. I’m going to need to defer to folks who did better than a “D” in geometry class. And, it just may come down to carving something with the angle grinder and attempting to duplicate it in mirror-image for the other side. That should create a lot of dust and noise, anyway. It’s pretty much a conical shape with elliptically-concave ends. Or, something technically-sounding like that. I’ll have to create the deck cambers and slopes under those corners, first, I suppose. And, naturally, the visor will need to be re-shaped to emulate the curves of the corner posts and trunk cabin below, as well. No rest for the hyper-imaginative, it would appear. OK, I’ll leave that as “easily distracted.” But, it’s time to get to some of them honey-do’s that have languished under Sysphus’ rock slide. Dan |

|